|

Hangzhou Supu Business Machine Co.,Ltd

|

| Payment Terms: | T/T,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Manual desk top double wire binding machinery with 2:1pitch CW360T

PRODUCT DESCRIPTION

Punched up to 35sheets per time

Max punching width:360mm

Pith:12.7mm

Disengagement punch pins:27

Number of punch pins:27

Max binding thickness:450sheets

Punch margin control to adjust punching depth

Full die disengaging pins for a clean punch of multiple paper sizes

Document measurement aides in the selection of the proper wire size in accordance to the document thickness.

Side margin control provides an evenly centered punch for all document sizes

It is light-weight and easy-to-use designed to provide top of the line punching and binding for your everyday needs,.

All Disengageable Dies for perfect punching of any size paper

This 2:1 Double Loop Wire Binding Machine CW360T is ideal for both office and home environments.

With an advanced ergonomical design, provides an economical option for your binding needs

TECHNOLOGY DATA

| MaxBind Capacity (20# paper) | 450Sheets |

| Max Punch Capacity (20# paper) | 35Sheets |

| Binding Format | Wire |

| Punching Method | Manual |

| Binding Method | Manual |

| Punching Format (Vertical/Horizontal) | Horizontal |

| Punch and Bind Capability | Yes |

| Max Punch Length | 360mm |

| Max Binding Length | 360mm |

| Number of Punch Pins | 27 |

| Disengageable Die Pins | 27 |

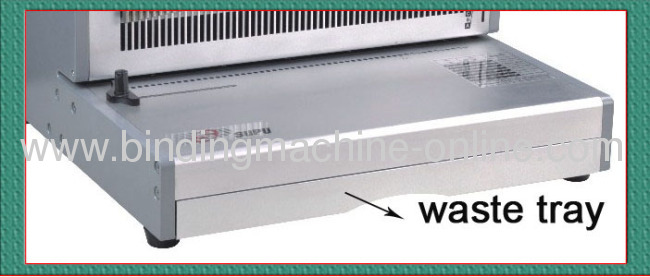

| Waste Compartment | Yes |

| Side Margin Control | Yes |

PRODUCT DETAIL

Dcument masure:according to your files thickness to pick the right number of sheets to punch,don't exceed the maximum number of allowed

Knob of wire size: can be adjustable according to your sheet thickness and wire size

Punching &binding handle:ensure your sheets are on the same line and feed the sheet horizon ,push the binding handle

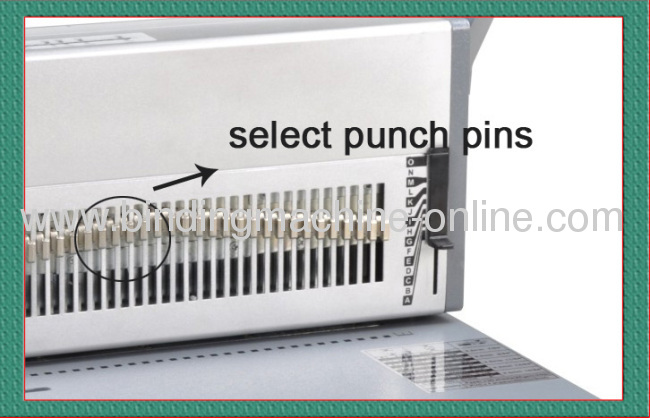

Select punch pins: disengagement punch pins made ofhard steel for a clean hole punch

Selectable paper stop: according to you files' zise, select paper positon ,keeping sheet aligning

Waste tray: large volume waste tray make you continuious work without empty punched times

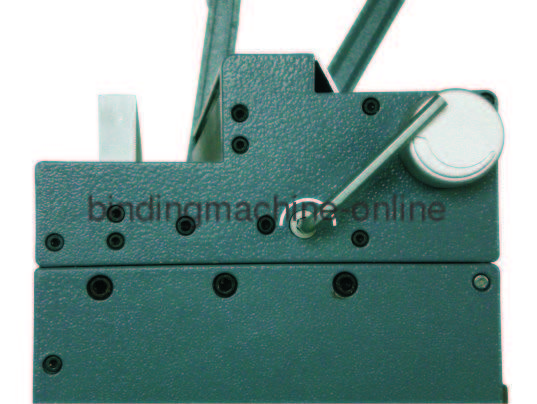

After long term use if it unbalance of closing bar , we will show you to fix it with a small tool in serveral simple steps as below:

1.

2.

3.

Loosen the two screws as indicated on the diagram a and b for one circuit only .

Check the unbalance of two closing bars by ruler or by eye then adjust the screw to left or right as

indicated on diagram accordingly .

Then test binding to check if the adjustment is ok or not .

If not perfect ,repeat as above until the perfect balance

s

WORKSHOP

CERTIFACTION

EXHIBITION