Product Name:Electrical heavy duty and multi-function binding machine

Internationa patent design

High speed punch capacity up to 22000 sheets per hour

Install 4 patterns punch dies at customer's request

The high quality precision die sets of this machine will last for years of production

All aluminum construnction make it durable and many years worry free

Features:

Electric foot pedal operation

Punch capacity: Up to 22000 sheets of 20 lb paper for an hour

Fully disengageable pins

Adjustable depth margin

Heavy duty motor and gearbox

With

comb binding,wire closing,calendar binding ;coil inserting together

Interchangeable punch die by manual revoving which is very easy and simple and every body can do it easily .No need to change the dies and even do not need any tooling when transfer one punching pattern into another pattern .

High capacity waste drawer hold much more shred papers requires less empty times

Features a bracket can be installed on the right side of the machine for punch A3 paper size

This is a great binding machine for people who want more options in a single

binding machine

High-performance machines built specifically for companies that do a lot of

book binding that requires different binding formats, such as comb , twin wire loop ,single

wire binding

The depth margin and side margin controls on the Electric Heavy Duty Multi-Function binding Machinery SUPER 4 IN 1 ensure that the all punches are well-centered and are placed at the correct spot along the margin

This multi-format versatility that makes the Electric Heavy Duty Multi-Function binding Machinery SUPER 4 IN 1 a popular choice among schools, colleges, print shops, corporate marketing departments, churches, and business development departments.

Features

A bracket can beinstall on the right side easily, toimprove the punch capacibility up to punchA3 size paper,Thisis another great feature about SUPER 4&1

the feauture will be showed as below

picture 1: insert A3 size paper, you'll find the paper is lager than worktable

picture 2: you'll see the left part of the paper were punched, but another partstill the same, how did we get the other part punched? don't worry, follow me to next picture

picture 3: turn over the punched paper, then make the pins ofbracket throught punched hole,punched with power foot pedal

picture 4: finally, you'll see the A3 size paper have been done punched perfectly

hard cover&pvc

hard cover&pvc

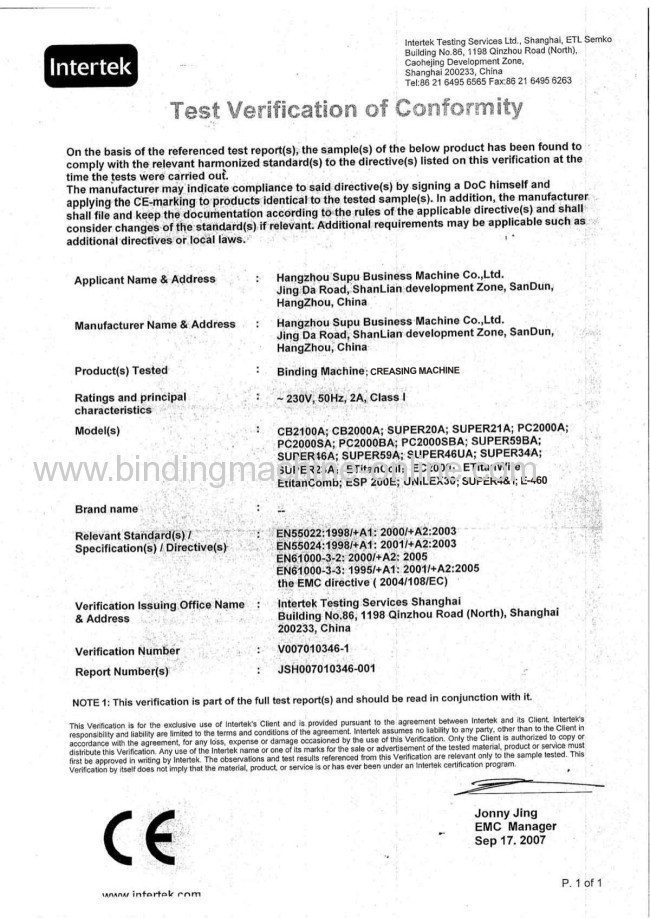

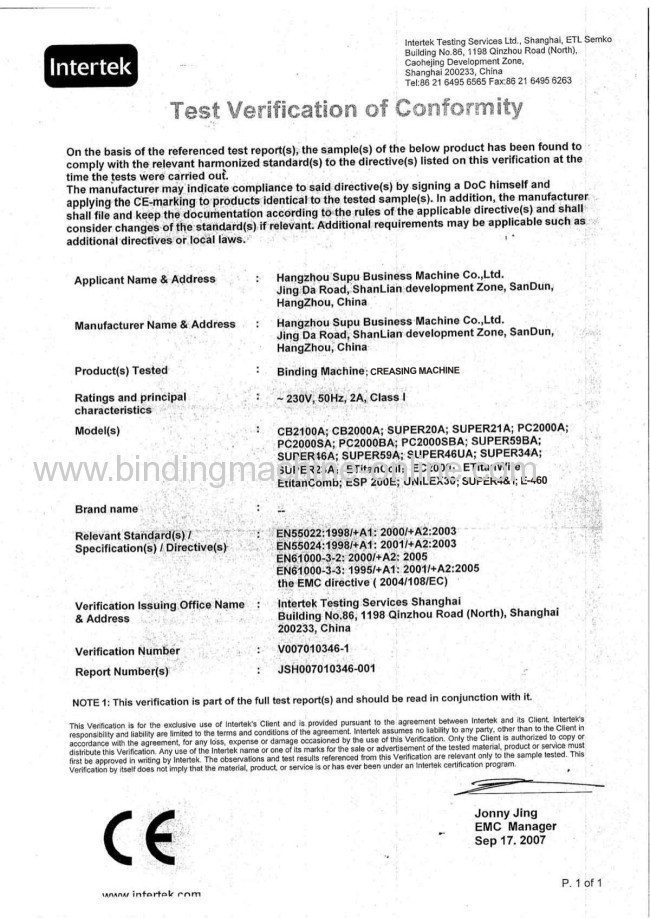

Certificate: