desktop document punching and Binding

| Payment Terms: |

T/T,L/C,D/P,WU |

| Place of Origin: |

Zhejiang, China (Mainland) |

Product Detail

Model No.:

PC2000B

Production Capacity:

1000pc/month

Delivery Date:

25days

width:

300mm

pith:

6.35mm

binding thickness:

150sheets

shipping weight:

14kg

port:

Shanghai

Means of Transport:

Ocean,Land,Air

Packing:

2pc/ctn

Brand Name:

SUPU

punching thickness:

25sheets

number of punch pins:

46

carton size:

55X48.5X48cm

packing:

2pc/ctn

payment:

T/T, West Union

Punching width:300mm(A4,11",B4,B5 format allowed)

Full 46 disengagement punch pins

punching capacity up to 25 sheets of 20lb each time

Manual Document Punching And Binding PC2000B

Descreption

Descreption

Punches 25Sheets of 20# Paper at a Time

Open Throat Allows for Punching of Larger Size Documents

6.35mm Pitch Hole Pattern

Side Margin Control Helps Centers Punched Holes Quickly and Easily

Adjustable Punch Margin Allows for Binding of Larger Documents

The Manual Document Punching And Binding is an easy to use, compact plastic coil binding machine, ideal for small volume offices and businesses. Featuring a set of new innovative designs from the engineers.

Punching and binding small volume coil book projects simple .

Side margin control, and an open throat design all in a lightweight machine case

Technology Data :

| Binding Format | Coil, Spiral |

| Punching Method | Manual |

| Binding Method | Manual |

| Punching Format (Vertical/Horizontal) | Horizontal |

| Punch and Bind Capability | Yes |

| Max Plastic Comb Punch Capacity (70g paper) | 25Sheets |

| Max Plastic Comb Bind Capacity (70g paper) | 150Sheets |

| Max Punch Length | 300mm |

| Max Binding Length | 300mm |

| Number of Punch Pins | 46 |

| Number of Disengageable Die Pins | 0 |

| Push Button Operation | No |

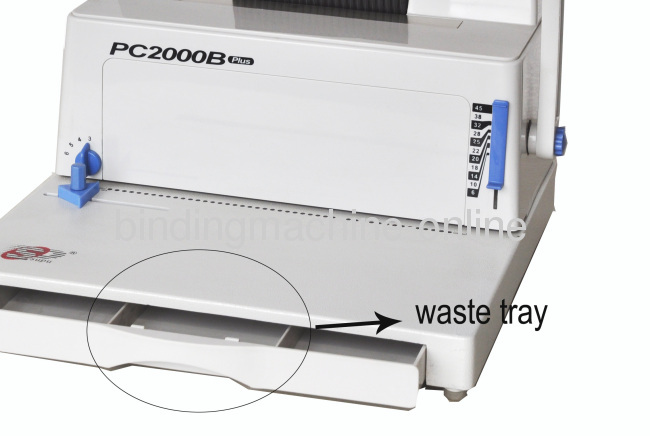

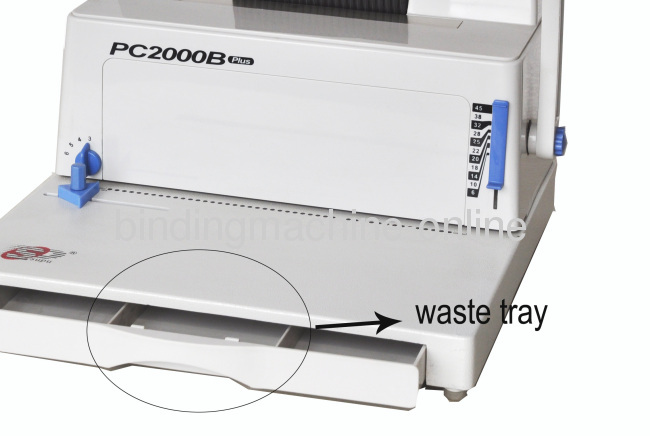

| Waste Compartment | Yes |

| Binding Diameter Guide | Yes |

| Side Margin Control | Yes |

| Margin Depth Selector | Yes |

Products details:

Selection paper stop:according to the size of files, select paper position

Depth side margin: according to your comb size adjust the depth side margin

Depth side margin: according to your comb size adjust the depth side margin

Dcument masure:according to your files thickness to pick the right number of sheets to punch,don't exceed the maximum number of allowed

Dcument masure:according to your files thickness to pick the right number of sheets to punch,don't exceed the maximum number of allowed

Punch handle:ensure your sheets are on the same line and feed the sheet horizon ,push the punch handle

Punch handle:ensure your sheets are on the same line and feed the sheet horizon ,push the punch handle

high volume wast tray allows for more time to work without empty punch

high volume wast tray allows for more time to work without empty punch

Bindingprocess

SETP 1: Ensure binding machine on a stable surface

Bindingprocess

SETP 1: Ensure binding machine on a stable surface

SETP 2:Plug the machine into a easily accessible main socket

SETP 2:Plug the machine into a easily accessible main socket

SETP 3:Feed paper horizon, according to your files' size adjust the paper stop

SETP 3:Feed paper horizon, according to your files' size adjust the paper stop

STEP 3:Inserting thecoil by electric

STEP 3:Inserting thecoil by electric

place the single loop wire to the top of roller,press the swtich button, inserting the punched sheets automatic

STEP 4: cut the single loop wire with plier

STEP 4: cut the single loop wire with plier

Loading

Loading

show room

Certificates

Certificates

Fair

Meet you next show in September Print 13

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com