Heavy Duty Electric paper hole Punch Mchine with interchangeable dies SUPER600

Descreption:

SUPER600 is a heavy duty electric punching machine, which can be used in industry, notebook producing factory ,enterprise and large organizations with firm design. With handsome and commodious appearance, The working platform is also large enough for you to work comfortably.

SUPER600 has advanced motor reducer and special-made mechanical clutch. Motor can run continuously and punching controlled by foot pedal which is easy and safe for operation.

Interchangeable die is easy and fast, which can punch various holes.Closing double wire is also available by changing punching dies into closing die and can close any size of double wire .

Technical data:

Punch thickness:5 mm

Wire closing: 3/16"1 1/4"(5.532 mm)

Punch width: 600mm

Adjustable side margin: 3-6mm

Punch speed: 4860 times/minute

Power voltage: AC220V,50HZ

Dimension: 1000x640x1110mm

Machine weight: 270KG

Motor power: 1.5KW

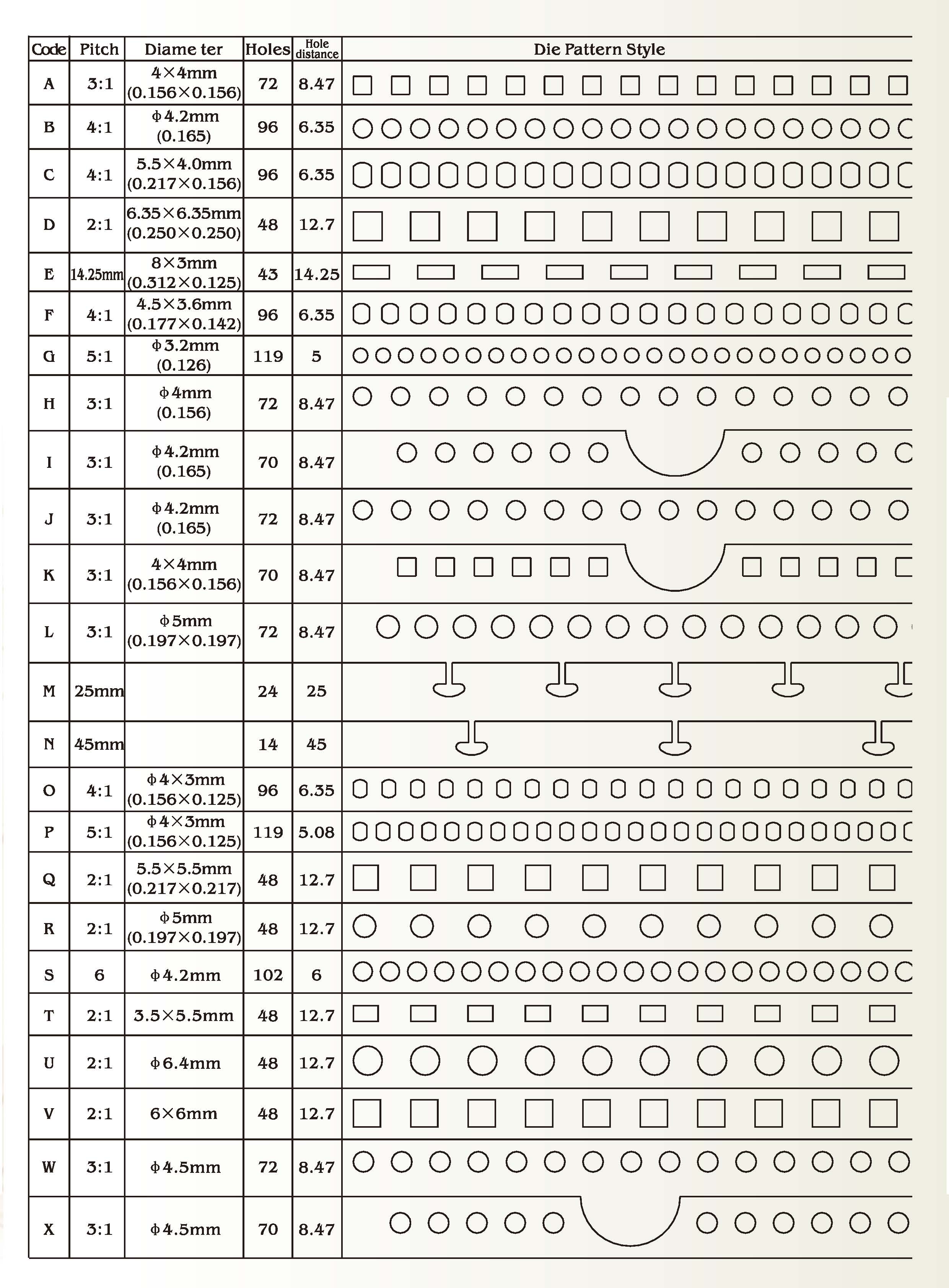

Please note: the punching dies are exchangeable and can be made according to customers' need.

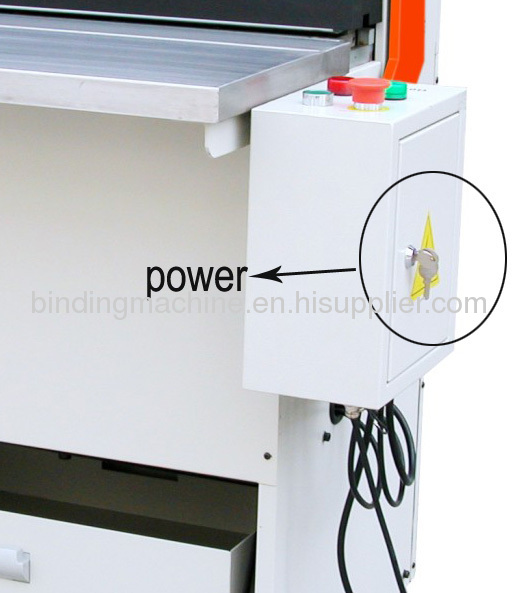

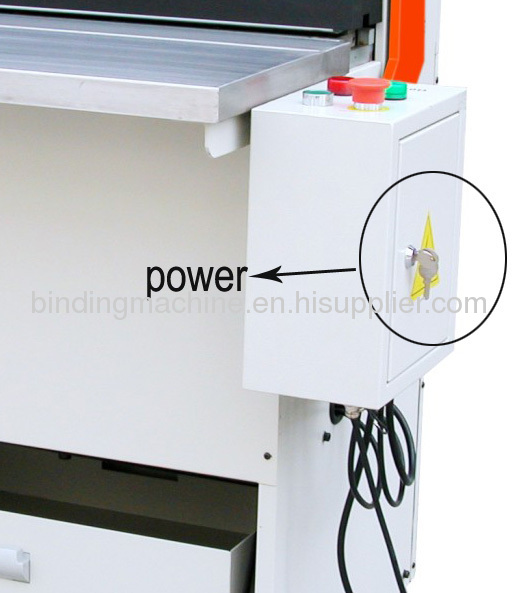

Power: This power control to make punch easy and enhance productivity efficiety

Power: This power control to make punch easy and enhance productivity efficiety

A powerful caoacity waste drawer hold much more shred papers, requires empty punched papers less frequently

A powerful caoacity waste drawer hold much more shred papers, requires empty punched papers less frequently

unching die into closing die on the same machine

unching die into closing die on the same machine

Oil-adding system make the machines durable and worry free .

Operation instruction:

1.Choose the cutting die according to the

binding hole.

2.Adjust the guiding rule to set reference point on the sheets, then please fasten the guiding rule.

3.Depth margin adjustment. The width of the margin is determined by the shape of the depth-margin bar that is inserted into the slot under the right side of the mold. It consists of A and B (show as below).

Depthmargin | 2mm | 3mm | 4mm | 5mm | 6mm |

Shape of the cross -section | Anotherdirection of B | Without depth- margin bar |

4.Try to punch with one sheet at first, until the margin and the hole are ok(,then start to work .It can punch about 50 sheets and 20 sheets PVC .

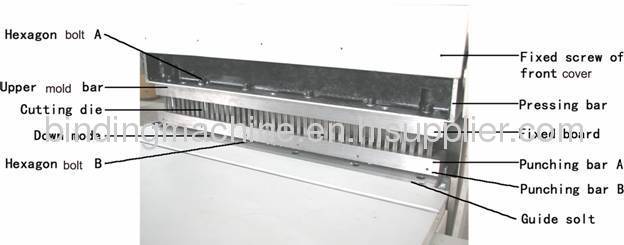

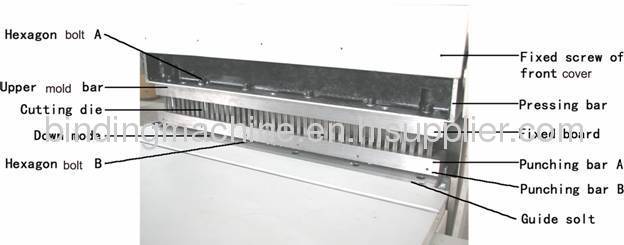

Disassemble and install punching dies.(see the accompanying drawing)

1.First, switch off the machine, open the cover,loose the fixed screws of it ,and take out cover upwards.

2.Second, insert two cushions between fixed board and punching bars A at eachside, to make sure that the blade of the punching pins are not abraded.

3.Third, Loose the hexagon screws A and B

4. Assemble the red bracket to the die andthen pull out the die by taking the bracketat the right side and keep it in a save place.

5.When installing, push the new dies along with the die guide slot and install. After that, fasten the hexagon boltA and hexagon bolt B and disassemble the red handle.

6. Turn the hexagon bolt A with tools in anticlockwise to take out of the cushion. After that, turn the hexagon nut A in anticlockwise once again for one or two circles to

check whether the machine can work normally. If yes ,start to work.

D. Methods for disengaging punching pins:

Depending on paper size and punching pattern, it can disengage the punching pins . But do not disengage more than 4 pins . The procedures are:

Switch off the machine,loose hexagon bolt A and take away the upper mode bar .

2.Knob the punching pins upwards staring from the down mode direction by using the copper bar. Then keep the pins for future use and cover the upper-mode bar, finally fasten the hexagon bolt.

Installing methods of wire closer. (with a accompanying drawing)

1.The mold for wire closing consists of pressingbar and down-mold board, which are fixed to the supporting girders and bases respectively, with magnet inside.

The procedures are as follows:

1. There are three adjustable screws on the pressing bar . Then insert the adjustable screws into the three holes from bottom to up. After that, add the cushion ,tight the adjustable screws .Then assemble the Screw cap and knob .

2. Install the down mold and push it into the guiding slot, then fasten the bolt.

Adjustment of wire closing

1. Adjust the closing size according to the ruler .

2. For the three adjustable knobs, The middle knob is only used to press wire down and the right and left knobs are for adjusting the size according the size of wire synchronouslu. So you can loose it before adjust the left and right knobthen firm and fasten the middle screw properly.

3.Test a piece of wire to close in order to see the closing according to the request. If the size is confirmed, fasten the screw cap.

FAIR

FAIR